Summary

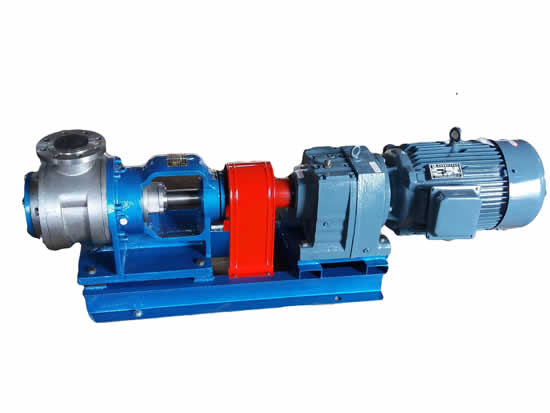

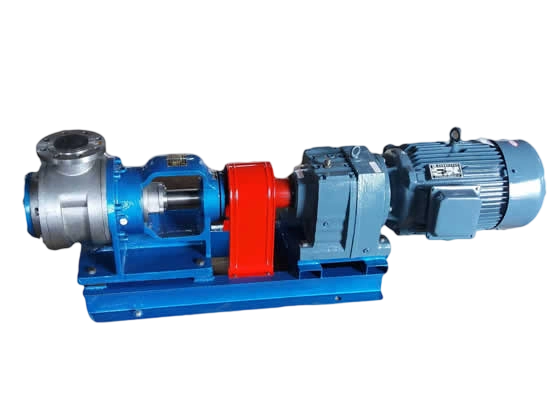

The NYP high viscosity pump is a positive displacement internal rotor pump. This type of pump has strong self-priming capabilities and is suitable for conveying viscous liquids without solid particles or fibers, including semi-solid liquids, with a maximum viscosity of up to 300,000 cSt. It features a compact size, light weight, low pulsation, low noise, stable operation, and long service life.

Scope of Application

Cast Iron Material: Suitable for high-viscosity fluid media without metal particles, applicable for petroleum and coating transfer conditions. Operating temperature range: -10°C to 200°C; applicable medium viscosity: 1.0 cSt to 300,000 cSt.

Stainless Steel Material: Suitable for chemical and food transfer conditions without metal particles. The stainless steel rotor pump offers corrosion resistance and meets hygienic transfer standards. Operating temperature range: -10°C to 200°C; applicable medium viscosity: 1.0 cSt to 300,000 cSt.

Applications

Chemical and Petrochemical: Petroleum, additives, polymers, lubricating oil, wax oil, asphalt, rosin, fibers, adhesives, starch, glue, detergents, grease, latex, resin, silicone oil, chemical fluids, high-viscosity fluids.

Paints and Coatings: Inks, dyes, paints, solvents, rubber solutions, adhesives, water-based paints, solvent-based paints, acrylic coatings, water-based coatings, solvent coatings, magnetic paints, varnishes, insulating varnishes, emulsions.

Plastics and Polyester: Polyester resin, epoxy resin, hardeners, isocyanates, plasticizers, polyol resins, surfactants, grease, resins, polymer solvents, synthetic resins, adhesives, pastes, plastics, polychlorinated biphenyl resins, acrylic resins, unsaturated polyester resins, alkyd resins, phenolic resins, melamine resins, polyurethane, polystyrene, AS resin, ABS resin, epoxy resin, vinyl acetate, artificial leather, polymer solvents.

Daily Chemical Industry: Sulfonic acid, alkylbenzene, fatty alcohol, detergents, shaving cream, face cream, shampoo, liquid soap, fragrances, hair conditioner.

Food Industry: Vegetable oil, lecithin, syrup, chocolate, yeast, protein, honey, glycerol, flavors, cheese, butter, spices, grease, glucose, animal and vegetable oils, edible oil, soybean oil, rapeseed oil, corn oil, butter, margarine, molasses, syrup.

Silicone Industry: Glass adhesive base, 107 glue, silicone rubber, silicone oil.

Structural Features

This series of gear pumps primarily consists of a front cover, inner rotor, pump body, outer rotor, sliding or rolling bearings, packing seal or mechanical seal, main shaft, and bracket.

The working characteristics of the internal meshing rotor pump include pulsation-free delivery, ensuring stable medium transfer with minimal vibration and low noise. It has strong self-priming capabilities. The inner and outer rotors rotate in the same direction, reducing wear and extending service life. Due to the design principle of the inner ring rotor, this pump is particularly suitable for conveying high-viscosity media.

Performance Parameters

| Model | Flow Rate (M³/h) | Discharge Pressure (MPa) | nominal size (mm) | Speed (rpm) | Connection |

|---|---|---|---|---|---|

| NYP7.0 | 1 | 1.0 | 40 | 257 | thread |

| NYP7.0 | 2 | 1.0 | 40 | 587 | thread |

| NYP7.0 | 3 | 1.0 | 40 | 960 | thread |

| NYP52 | 5 | 1.0 | 50 | 208 | flange |

| NYP52 | 8 | 1.0 | 50 | 303 | flange |

| NYP52 | 10 | 1.0 | 50 | 357 | flange |

| NYP52 | 12 | 1.0 | 50 | 357 | flange |

| NYP111 | 18 | 1.0 | 80 | 305 | flange |

| NYP111 | 22 | 1.0 | 80 | 359 | flange |

| NYP111 | 28 | 1.0 | 80 | 479 | flange |

| NYP111 | 30 | 1.0 | 80 | 505 | flange |

Reviews

There are no reviews yet.